No 1 Underground Tank Cleaning Company without Man Entry

No of Tanks Cleaned Till Date

0

Testimonials

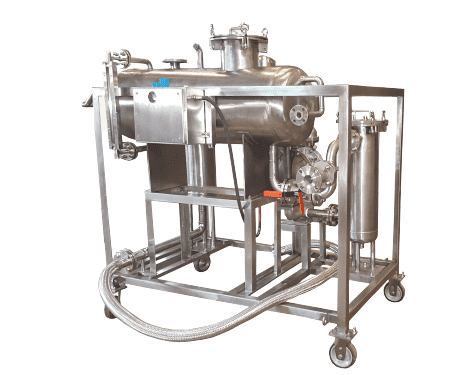

Our Products & Services

Clients

About Us

Our Purpose, internally we refer to it as Manan and Sadhana

We exist to Explore and find a better way of solving problems.

हमरा वजूद है छान-बीन करना और समस्या को हल करने का एक बेहतर तरीका खोजना !

By identifying root cause and experimenting with different options to provide innovative solutions.

मूल कारणों की पहचान करके और विभिन्न विकल्प के साथ प्रयोग करके उन्नतिशील समाधान प्रदान करना !

Our Core Values, internally we refer to it as Spiritual Foundation

- We hold ourselves responsible for our products, services, our team, our suppliers, our contractors and our believers (clients), the application we are working on.

- We believe in fulfilment of commitments to our believers (clients), our team, our suppliers, our contractors.

- We believe in treating all stakeholders with respect and dignity.

- We believe in being fair and just to all.