Heaters

Tristar believes in engineering products which last for generations. Rigorous quality assurance programs incorporating rigid testing standards for each product enables Tristar to deliver products that give long life & trouble free service.

Immersion Heaters

- Threaded Screw plug

- Benefit list write here

- Flange – Standard and customized

Tubular Heaters

Tubular Direct Immersion Heaters are specifically designed for direct contact heating of water, oils, viscous liquids, solvents, process solutions and gases. As all heat is generated within the liquid or process, virtually 100% heat transfer is achieved. Further, various options permit very tight process temperature control. The basic mounting options of these heaters like threaded screw plug connections, flanges or simple over-the-side designs help our clients with easy installation of the heaters.

Features

- Designed for use in tanks and pressurized vessels, they are easy to install and maintain to provide heat for many processes.

- The direct immersion method is energy efficient and easily monitored and controlled.

- These heaters are available with heating elements made of copper, steel, stainless steel, cast iron, titanium, and PFA coated.

- A wide selection of kilowatt ratings, shapes and mounting methods are available to suit many different types of applications.

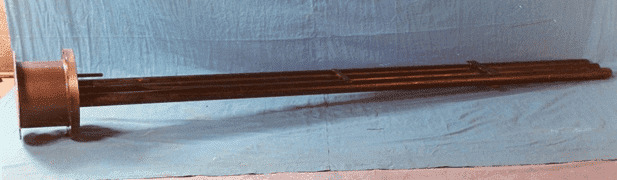

Threaded Screw plug immersion heaters consist of tubular elements brazed or welded to the plug/ tube sheet. They are screwed to a coupling welded on the tank or to the threaded opening in the tank wall.

The point of using dummy text for your paragraph is that it has a more-or-less normal distribution of letters. making it look like readable English.

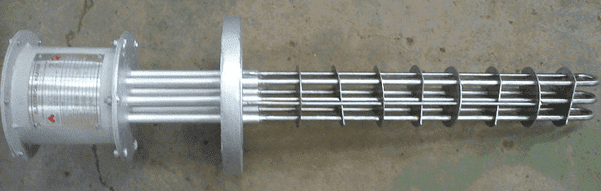

Flanged Immersion Heaters

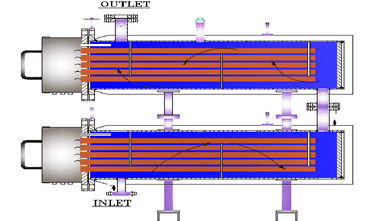

Flanged immersion heaters can be manufactured using tubular elements or cartridge element inserted in a seamless pipe welded to the flange. In this case the flange also acts as a tube sheet on which the pipes are welded. Flange Heaters are installed by bolting to a matching flange welded to the tank wall (nozzle). These are designed for use in tanks and pressurized vessels.

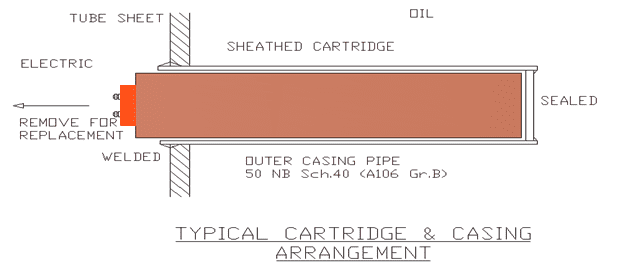

Flanged immersion heater with cartridge elements is preferred for tanks holding viscous substances. The cartridge elements can be easily replaced without dismantling the heater body or draining the tank.

Applications where Flanged immersion heater with cartridge heating elements is preferable.

- Designed for use in tanks and pressurized vessels, they are easy to install and maintain to provide heat for many processes.

- The direct immersion method is energy efficient and easily monitored and controlled.

- These heaters are available with heating elements made of copper, steel, stainless steel, cast iron, titanium, and PFA coated.

- A wide selection of kilowatt ratings, shapes and mounting methods are available to suit many different types of applications.

Advantages of Tristar Heaters

- Customized to suit your requirements taking into consideration process parameters.

- Optimal watt density for long trouble-free life, no charring / coking of fluid.

- Even Heat distribution over the surface of the element avoiding hot spots

- Easily replaceable without dismantling the heater body or emptying the contents of tank, feature on request.

- Various temperature control and measurement devices.

- Two thermostats one for Safety and another for Control or RTD for Control.

- 1 kW to 200 kW single heater, higher capacities can be designed and manufactured

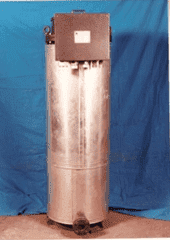

Suction Heater

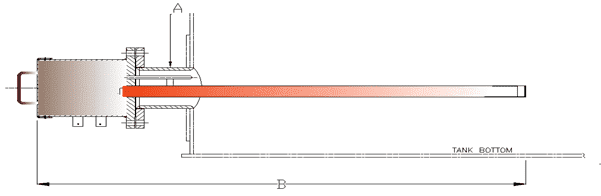

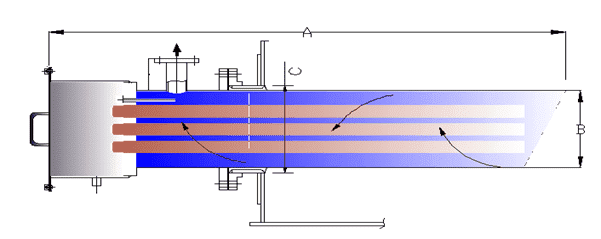

Suction Heater are specifically designed to heat only that amount of material that is to be pumped from a large storage tank. The outlet nozzle is attached to the pump suction. The heater heats the material inside the heater pipe body which is then drawn through the heater into the suction side of the pump.

Application Outflow / Suction Heaters

Used in tanks from which viscous fluids are to be pumped.

- HFO / FO

- Asphalt

- Molasses.

- Other high viscosity Materials.

- Tar

Features

- Designed to heat viscous fluid as it flows through the heater to bring it to pumpable temperature

- Used in large storage tanks to provide for quick flow through heating of viscous materials

- Preferable Watt density offered 0.75 to 1.5 w/cm² or 4.8 to 9.6 w/in²

- Two thermostats one for Safety and another for Control

- RTD available on request.

- Replaceable heating element type to be able to replace when required without emptying the contents of the tank.

- Element construction - Tubular or Cartridge

- Connection type - Flanged

Advantages of Tristar Suction / Outflow Heaters.

- Heating elements easily replaceable without dismantling the heater body

- Replacement of heater elements without draining the tank

- Customized to suit your application taking into consideration process parameters.

- Optimal watt density for long trouble-free life, no charring / coking of fluid.

- Two thermostats / RTD one for control one for safety

- 1 kW to 200 kW single heater, higher capacities can be designed and manufactured

The selection of a proper heater for your process is a crucial, it involves selection of the mounting, appropriate heating element sheath material to withstand temperature, corrosion etc. and correct watt density to ensure long, trouble free service and preserving product integrity. We would be happy to help you with selection of the correct heater. Please let us know the following details.

- Media to be heated

- Viscosity

- specific heat

- density

- corrosive properties.

- Contaminants or pH level in the media

- Pressure

- Operating Pressure

- Temperature

- Operating Temperature

- Ambient Temperature

- Volume to be heated

- Flow rate (For Outflow and Inline Heater)

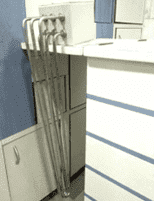

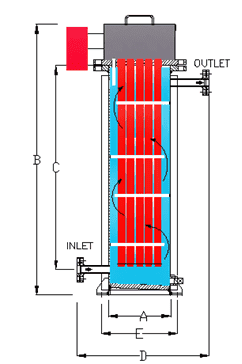

Inline Heater

- Available with Tubular Elements, Open Bobbin or Cartridge Elements.

- Optimum Heat Transfer

- Easy replacement for open bobbin and cartridge heaters.

- Optimal watt density for long trouble free life, no charring / coking of fluid

- Available from 3 kW to 500 kW

- Custom made to suit your requirements

- Two thermostats one for Safety and one for Control.

- RTD is available on request.

- Long trouble-free service.

- Immersion heaters in the HFO Storage Tank to maintain the HFO temperature in the tank.

- Outflow / Suction heaters in the tank, to raise the temperature to make it flowable.

- Inline Heaters in the pipeline before the burners, to raise the temperature for ignition.

Tristar designs and manufactures all the heaters required to optimise power utilisation for your plant. Please let us know the Tank Capacity and flow rates for us to design and quote for the heaters.

- Screw Plugs- Brass and SS 1” to 3" BSP or NPT

- Flanges - As per ANSI B16.5, CS, SS 304, SS 316

- Heating Elements( Casing Pipes / Tubular Elements) - Copper, CS, Passivated SS, SS 304, SS 316, SS321, Incoloy, and Titanium and Teflon / PTFE (Polytetrafluorethylene) coated.

- Body Shell - CS, SS 304, SS316, SS321 etc.

- Resistance Wire – Kanthal

- Temperature Controls and Safety - Thermostats, RTD, Thermocouple and PID

- Accessories - Drain Valve, Pressure Gauge, Pressure Relief Valve, Flow Switch, Pressure Switch, Pump Interlock Relay, Low Liquid Cutoff.

Electrical Tests - Resistant Test, Insulation Test, High Voltage Test, kW, Voltage and Amphere Test, Hydrostatic Test(Inprocess)

- Water Heating , Process Solutions

- Heat Transfer Oil Heating

- Fuel Oil / Water Pre Heating

- Heavy oils Tank heating

- Freeze Protection

- Steam, Air and Gas Heating

- Boiler equipment, Process air equipment, Food Processing equipment, Plating Baths, Cleaning and Rinsing tanks, etc.

- Jacket water heating

Applications where cartridge / open bobbin heating elements can be used.

- Large Diameter tank content Heating

- Heavy weight Fuel oil / Asphalt

- Fuel Oil Preheating / Jacket Water Heating

- Plating Baths, Cleaning and Rinsing tanks

- Insulators made from typical properties of ceramics such as cordierite, steatite, etc.

- Excellent physical, thermal and electrical properties.

- Easy replacement.

- Very low watt density on casing pipes ensures longer life of elements.

- Available from 3 kW to 240 kW

- Watt Density: 1 w/cm² to 1.5w/cm² (6.45 to 9.6 w/in².)

- Custom made to suit your requirements

- Two thermostats one for Safety and another for Control