Basket Strainer

- Fuel oils like Petrol, Diesel, ATF, Furnace Oil, LSHS etc

- Lube Oils,

- Vegetable Oils

- High viscosity liquids

- Chemical Solutions

- Cooling water

- Process water, boiler feed water etc

- Coarse filtration of sea and river water.

- Custom designed to suit process parameters of flow rate, pressure drop and filtration.

- Larger Basket Area (Gross Filtration Area) – at least 25 times the cross-section inlet area, resulting in lesser pressure drop and lesser cleaning frequency.

- Compact design- Can be mounted on pipelines like a valve.

- Positive Filtration- Specially designed basket seating arrangement with spring ensures no liquid bypass

- Degree of Filtration – Coarse filtration down to 5 microns or less can be achieved from a wide choice of filter media.

- Reduced Frequency of Cleaning and maintenance– Higher Gross filtration area and multiple baskets ensure that the frequency of cleaning is low.

- Inline or Offline construction available.

- Multiple filtration element design options available.

- Available in Carbon steel, Stainless steel of various grades. Galvanization on request.

- Standard Sizes – 25 NB to 500 NB, Larger sizes available.

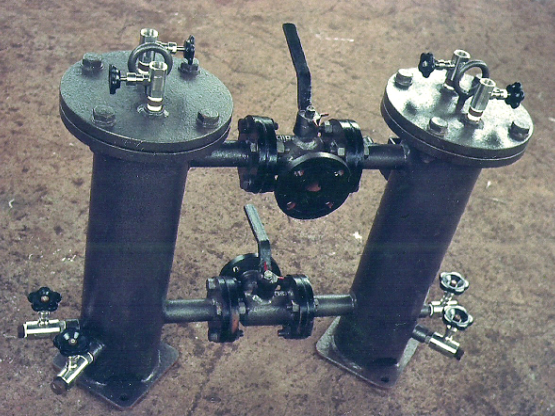

3 Way Valve Design

• Used in continuous processes where the fluid flow cannot be interrupted periodically for cleaning purpose or other maintenance.

• Ensures smooth flow of fluids and protects the equipment on the line from harmful flow contamination by capturing dirt and debris

• Construction deign – Three Way Valve or Four Isolated Valve design, Inline or Offline construction• Elements –Inwell Type or Cross Element, Single or Multiple elements depending on size.

Main Features and Advantages

• Custom designed to suit process parameters of flow rate, pressure drop and filtration.

• Larger Basket Area (Gross Filtration Area) – at least 25 times the cross section inlet area, resulting in lesser pressure drop and lesser cleaning frequency.

• Positive Filtration- Specially designed basket seating arrangement with spring ensures no liquid bypass.

• Degree of Filtration – Coarse filtration to 5 microns or less can be achieved from a wide choice of filter media.

• Reduced Frequency of Cleaning and maintenance– Higher Gross filtration area and multiple baskets ensure that the frequency of cleaning is low.

• Available in Carbon steel, Stainless steel of various grades. galvanization on request.

• Standard Sizes – 25 NB to 500 NB, Larger sizes available

- Used in continuous processes where the fluid flow cannot be interrupted periodically for cleaning purpose or other maintenance.

- Ensures smooth flow of fluids and protects the equipment on the line from harmful flow contamination by capturing dirt and debris

- Valves for diversion of flow – Three Way Valve or Four Isolated Valve design

- Pipline - Inline or Offline

- Elements –Inwell Type or Cross Element, Single or Multiple elements depending on size.

Main Features and Advantages:

- Custom designed to suit process parameters of flow rate, pressure drop and filtration.

- Larger Basket Area (Gross Filtration Area) – at least 25 times the cross-section inlet area, resulting in lesser pressure drop and lesser cleaning frequency.

- Positive Filtration- Specially designed basket seating arrangement with spring ensures no liquid bypass

- Degree of Filtration – Coarse filtration to 5 microns or less can be achieved from a wide choice of filter media.

- Reduced Frequency of Cleaning and maintenance– Higher Gross filtration area and multiple baskets ensure that the frequency of cleaning is low.

- Available in Carbon steel, Stainless steel of various grades. Galvanization on request.

- Standard Sizes – 25 NB to 500 NB, Larger sizes available